Selecting High-Quality Cutting Tooling for Long Tool Life

Share

When it comes to woodworking tools, quality matters. Investing in high-quality tooling can save money in the long run by reducing replacement costs, minimizing downtime, and improving cut quality.

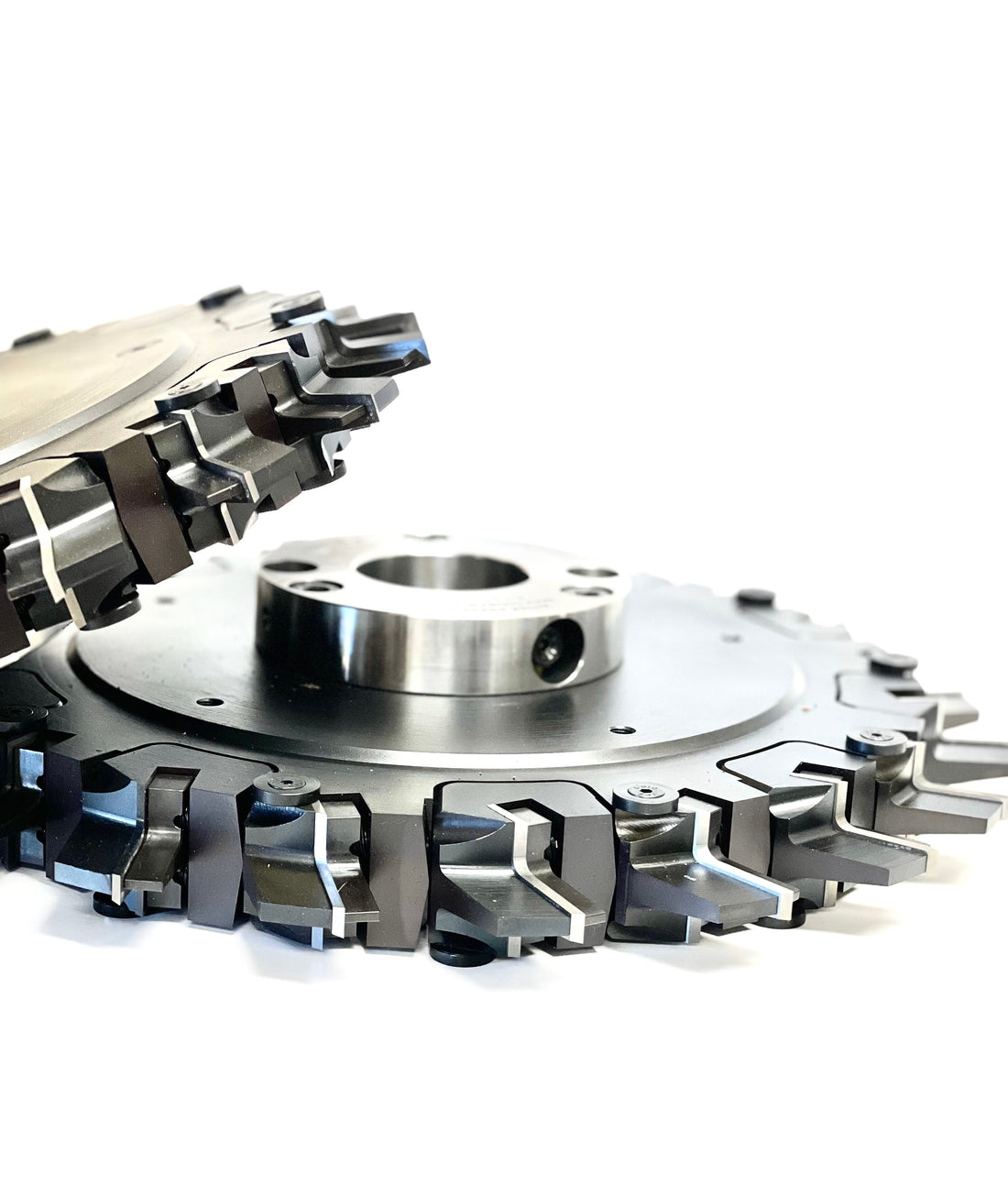

The material and manufacturing process of a tool determine its durability. Solid carbide and polycrystalline diamond (PCD) tools are excellent choices for longevity and precision. High-quality carbide retains sharpness longer than cheaper alternatives, reducing the frequency of sharpening.

Coatings also play a significant role in tool life. Titanium, aluminum, and diamond-like coatings help reduce friction, dissipate heat, and protect against wear. A well-coated tool experiences less buildup, maintaining sharper edges for extended periods.

Choosing the right tool for the job is equally important. A premium cutter with the wrong geometry for a particular material will still wear out quickly. Understanding factors like flute design, rake angle, and cutting edge composition ensures that you select the best tool for each application.

Though budget-friendly tools may seem appealing, they often dull quickly, leading to frequent replacements and inconsistent cuts. Investing in premium-quality cutting tools not only enhances performance but also provides long-term savings by extending tool life and maintaining production efficiency.

By selecting high-quality tools, using proper feeds and speeds, and maintaining a regular sharpening schedule, you’ll get the most out of your investment, ensuring precise and efficient woodworking operations.